SKYPE: Senfeng ![]() call 86-15132980935

call 86-15132980935

SKYPE: Senfeng ![]() call 86-15132980935

call 86-15132980935

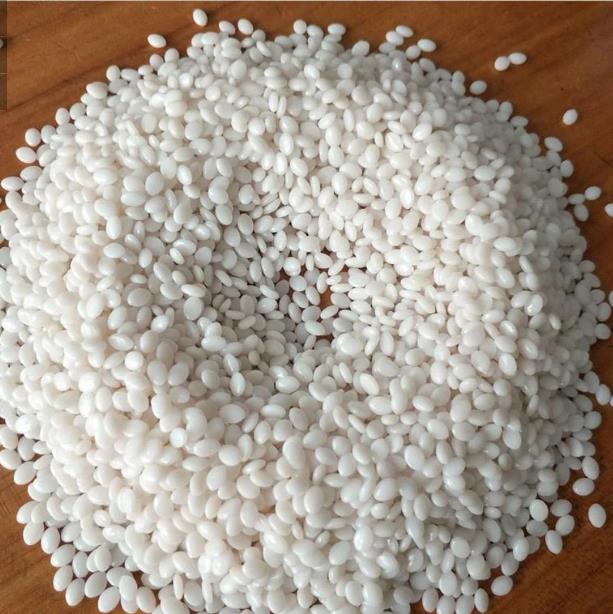

Description :100% biodegradable, compostable, easily synthesized by microorganisms within 90 days, non-toxic, low carbon, energy saving. It is a homogeneous mixture of thermoplastic starch (TPS) and PBAT. Provides high levels of mechanical strength, excellent elongation and toughness. 1. Good tensile strength, close to traditional LDPE; 2. Heat resistance and impact performance; 3. Good biodegradation. In the landfill or water is degraded to H20 and CO2 by microorganisms, in soil and water to maintain zero harmful substances, completely non-toxic; . Pleasant cornstarch/lemon flavors. A soft, smooth touch; 6. Competitive pricing.

Polylactic acid, also known as polylactide, belongs to the polyester family. Polylactic acid is a polymer obtained by polymerizing lactic acid as a main raw material. The raw material source is sufficient and can be regenerated, and corn, cassava and the like are mainly used as raw materials. The production process of polylactic acid is non-polluting, and the product can be biodegraded to achieve circulation in nature, so it is an ideal green polymer material.

Material Characteristics

Polylactic acid has good thermal stability, processing temperature of 170-230 degrees, good solvent resistance, and can be processed in multiple ways, such as extrusion, spinning, double stretching, and injection blow molding. In addition to biodegradability, products made from polylactic acid have good biocompatibility, gloss, transparency,hand feeling and heat resistance. It also has certain bacteria resistance, flame retardancy and UV resistance, so it is widely used , can be used as packaging materials, fibers and nonwovens. Currently used mainly in clothing (underwear, outerwear), industry (construction, agriculture, forestry, paper) and health care ,etc field

| Items | Standard | Unit | TRBF93 |

| Density | ISO1183 | g/cm3 | 1.23 |

| Melting Point | DSC, 10ºC/min | ºC | 140-150 |

| Melt Flow index | ISO1133 | g/10min (190 ºC,2.16kg) | ≤9 |

| Tensile Strength (MD) | ISO527 | MPa | ≥22 |

| Tensile Strength (TD) | ISO527 | MPa | ≥15 |

| Elongation at Break (MD) | ISO527 | % | ≥150 |

| Elongation at Break (TD) | ISO527 | % | ≥380 |

| Tear Strength (MD) | ISO527 | mN | ≥1600 |

| Tear Strength (TD) | ISO527 | mN | ≥3500 |

call: 86-15132980935 Hebei Senfeng Technology Co., Ltd